8Cr13MoV is one of the most common budget-to-midrange stainless steels in folding knives. It balances hardness, toughness, and corrosion resistance at a price point most buyers accept.

Pick 8Cr13MoV if you need a well-rounded stainless steel for EDC that’s easy to sharpen, offers decent edge retention, and works across urban and light outdoor tasks. Avoid it for extreme, prolonged hard use.

I’ve produced thousands of OEM knives in 8Cr13MoV for global brands. When treated well, it performs above its price—it’s forgiving for users and consistent for makers.

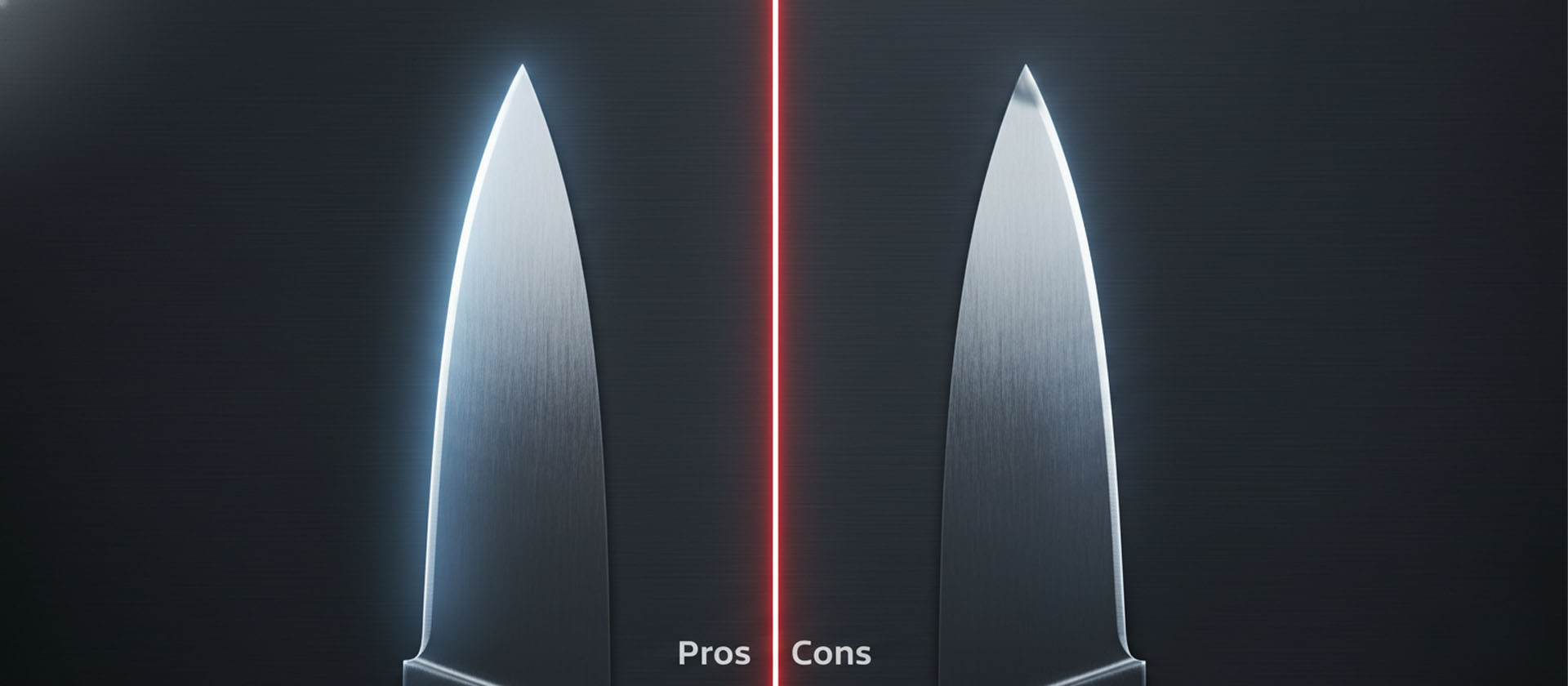

Quick Answer: Should You Pick 8Cr13MoV? (Pros & Cons in One Minute)?

If you want the short version:

8Cr13MoV offers moderate edge retention, good corrosion resistance, and forgiving sharpening, making it suitable for most practical EDC tasks without overspending.

Pros:

- Balanced performance for price

- Easy to sharpen with basic tools

- Good rust resistance in normal EDC use

- Versatile edge for slicing and light utility

Cons:

- Edge retention lower than premium steels

- Can chip if over-stressed at high hardness

- Not best for extreme, abrasive work environments

What is 8Cr13MoV? Composition Basics and Close Cousins (AUS-8/440B-ish)?

8Cr13MoV is a Chinese stainless steel designed for affordable, versatile knife production.

It has ~0.8% carbon and ~13% chromium, plus molybdenum and vanadium for corrosion resistance and grain refinement. It’s similar to Japanese AUS-8 and Western 440B.

Typical composition:

| Element | % Content |

|---|---|

| Carbon (C) | ~0.80% |

| Chromium (Cr) | ~13% |

| Molybdenum (Mo) | ~0.30% |

| Vanadium (V) | ~0.20% |

| Manganese (Mn) | ~1% |

| Silicon (Si) | ~1% |

Molybdenum adds pitting resistance in damp environments. Vanadium refines carbides for a smoother edge.

Heat Treatment Realities: Typical HRC Ranges and Their Impact on Use?

Heat treat quality changes the steel’s character.

8Cr13MoV is normally hardened to HRC 57–59, giving it a mix of edge life and toughness while keeping it easy to maintain.

| HRC | Benefit | Trade-Off |

|---|---|---|

| 57 | High toughness | Shorter edge life |

| 58 | Balanced | Slightly more brittle risk |

| 59 | Longer edge retention | Less forgiving under impact |

Consistency in heat treat is more important here than chasing highest hardness—poor practice can cause chipping.

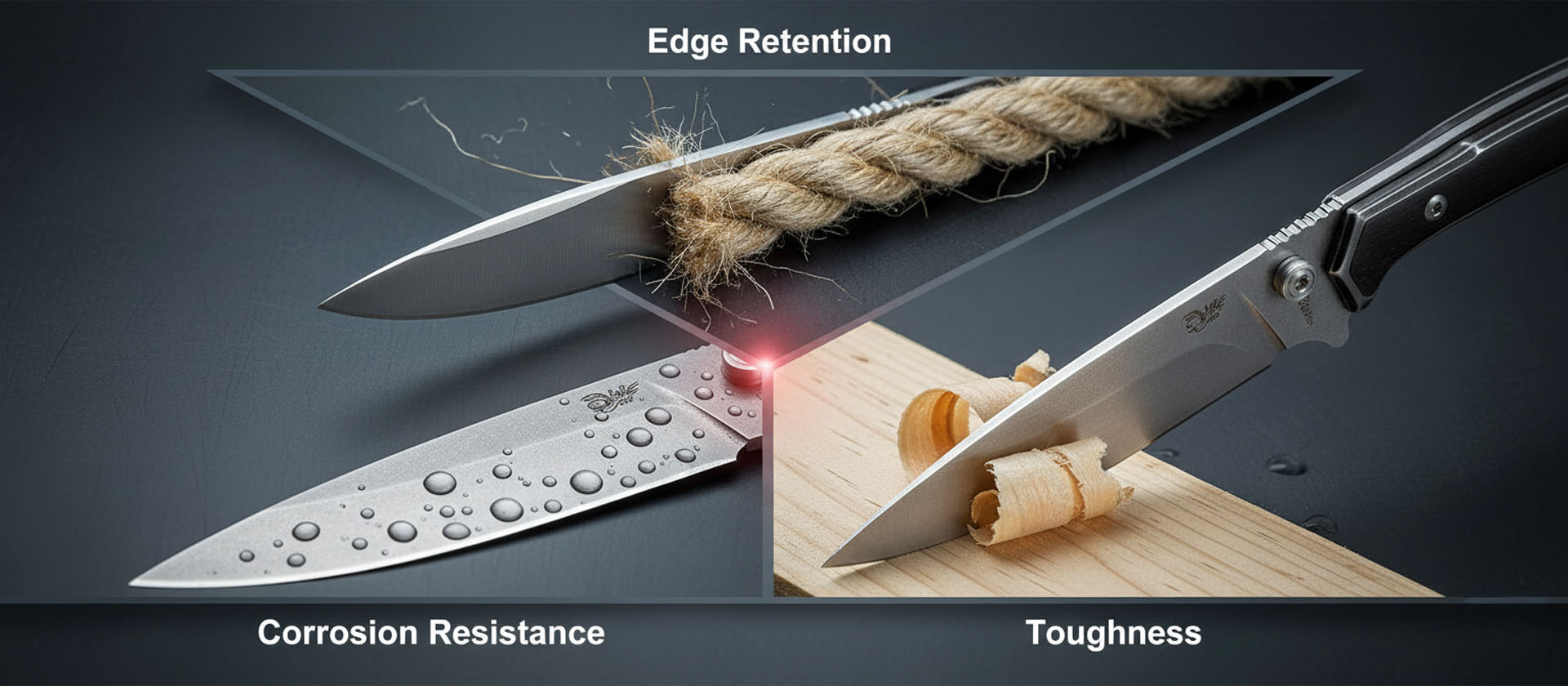

Performance Profile: Edge Retention, Corrosion Resistance, Toughness Trade-Offs?

8Cr13MoV aims for balance, not extremes.

You get mid-level edge retention, solid rust resistance, and forgiving toughness, making it suitable for mixed EDC cutting instead of heavy construction or bushcraft.

| Property | Rating | Note |

|---|---|---|

| Edge retention | Moderate | Needs touch-up after daily use |

| Corrosion resistance | Good | Handle damp use fine |

| Toughness | Good | Edge damage is rare in light tasks |

| Ease of sharpening | High | Works with basic stones/rods |

Sharpening Behavior: Beginner-Friendly Angles, Stones, and Stropping Tips?

Ease of sharpening is a plus for budget steels.

Use angles ~30–40° inclusive, medium grit stones, and strop with compound for a polished edge. Beginners can learn well on 8Cr13MoV.

| Recommended: | Tool | Benefit |

|---|---|---|

| 800–1000 grit stone | Restores edge quickly | |

| Leather strop + compound | Refines and polishes edge | |

| Ceramic rod | Fast daily touch-ups |

This steel responds fast to honing—just a few passes bring back bite.

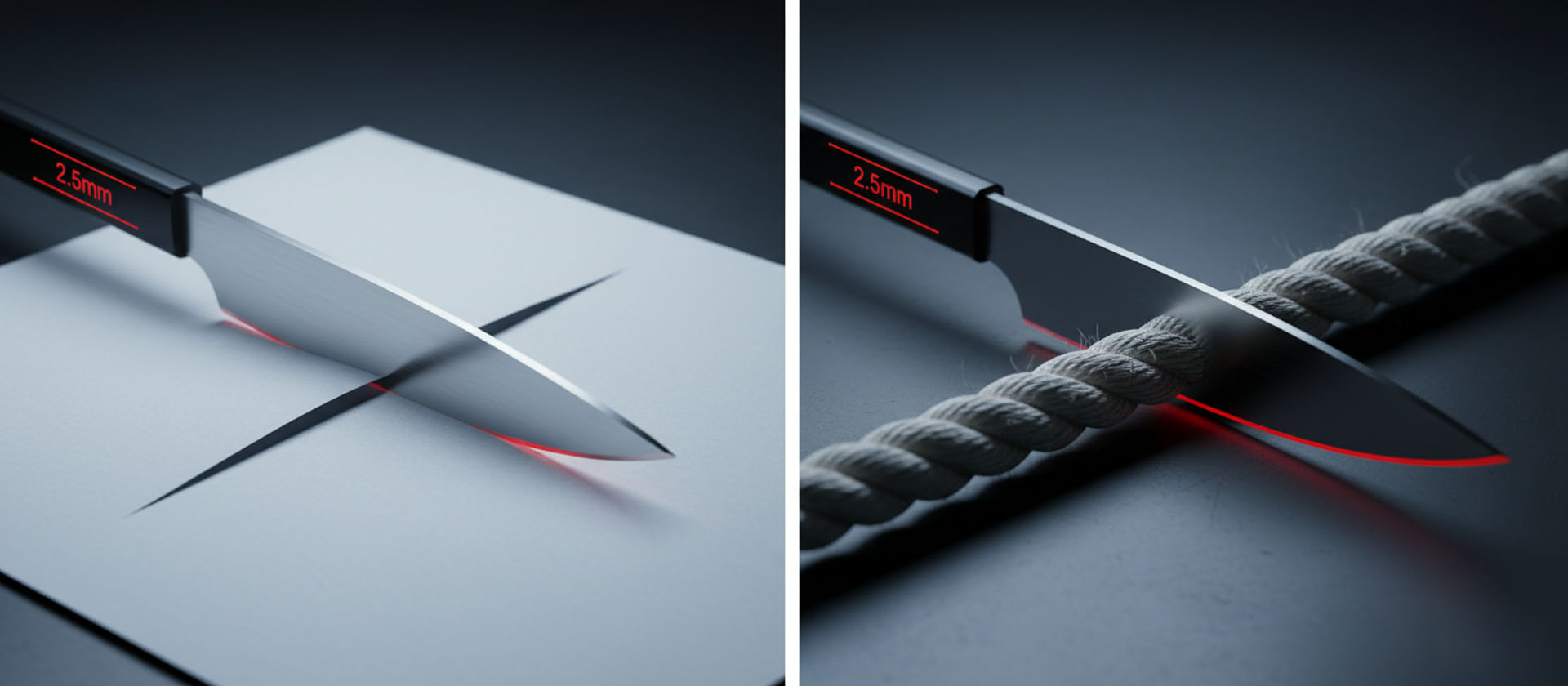

Geometry Over Steel: Stock Thickness, Edge Width, and Grinds That Make It Sing?

The right grind can push performance up.

Thin stock (2.5–3 mm), narrow edge bevels, and flat or high hollow grinds make 8Cr13MoV cut efficiently and seem sharper longer.

Thick spines with obtuse edges reduce slicing ability and make dulling more obvious. Production runs for EDC shapes work best with tapered tips and fine edges.

Surface Finishes That Help (and Hurt): Stonewash/Satin vs. Aggressive Bead-Blast; Coatings?

Finish choice affects both appearance and corrosion defense.

Stonewash and satin balance looks and maintenance. Heavy bead-blast can trap moisture. DLC/PVD coatings add style but don’t change underlying steel limits.

In fishing or food environments, avoid bead-blast without sealing—it raises maintenance needs.

Best Use Cases: Urban EDC, Light Utility, Food Prep, Travel-Friendly Carry?

Pick tasks that fit the steel.

8Cr13MoV suits small to mid-size folders for city carry, office use, travel, and light food prep where heavy impact isn’t expected.

| Use Case | Benefit |

|---|---|

| Urban EDC | Versatile cutting |

| Food prep | Rust protection works well |

| Travel knives | Easy edge maintenance |

| Gift knives | Good price/value balance |

Where It Struggles: Abrasive Media, Prolonged Hard Use, Prying/Batoning?

Avoid pushing it into extremes.

8Cr13MoV dulls quicker against abrasive media, fatigues in long hard-use cycles, and can chip if used for prying or batoning.

It’s not a replacement for harder, wear-resistant steels in industrial or heavy outdoor work contexts.

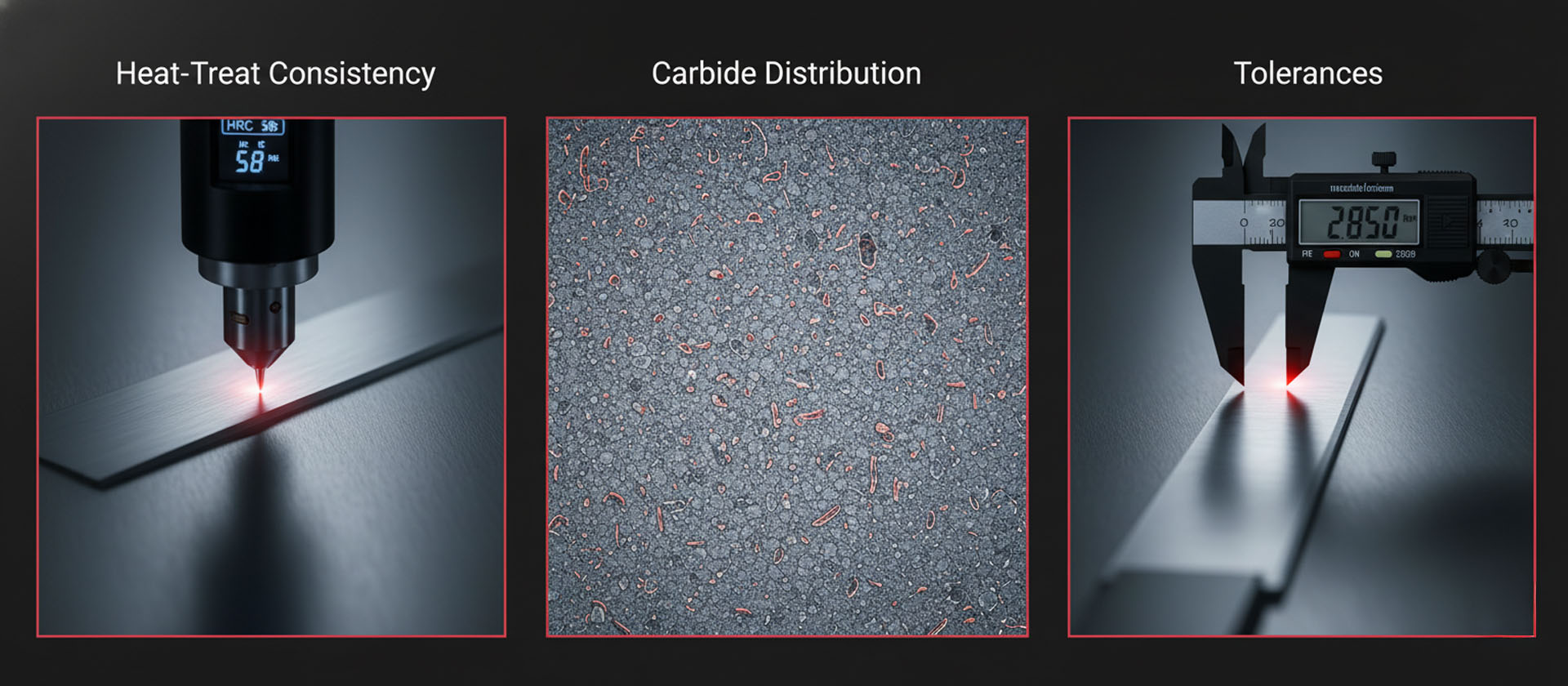

QC Variables to Watch: Heat-Treat Consistency, Carbide Distribution, Tolerances?

Not all 8Cr13MoV knives are equal.

Watch for consistent hardness in QC tests, clean grind lines, and uniform carbide patterns for best performance.

Poor heat treat lowers performance more than the steel’s chemistry would suggest—raising customer complaints.

Buyer’s Checklist: How to Evaluate an 8Cr13MoV Knife Beyond the Steel Stamp?

Move past the marketing label.

Check hardness spec, grind quality, fit and finish, and pivot smoothness before purchase.

Checklist:

- HRC 57–59 on spec

- Centered blade and even bevels

- No moisture traps in finish

- Comfortable handle shape

- Smooth, reliable lockup

Close Alternatives by Budget & Feel: 5Cr15MoV, 7Cr17MoV, 9Cr18MoV, 12C27, 14C28N, D2, 440C, Nitro-V?

Know your nearby options.

Lower-cost: 5Cr15MoV, 7Cr17MoV. Higher performance: 9Cr18MoV, 12C27, 14C28N. Tool steels like D2 and stainless like 440C or Nitro-V for harder use.

| Steel | Retention | Corrosion | Hardness |

|---|---|---|---|

| 5Cr15MoV | Low | High | HRC 55–57 |

| 7Cr17MoV | Low-Mid | High | HRC 56–58 |

| 9Cr18MoV | Mid-High | High | HRC 58–60 |

| 12C27 | Mid | High | HRC 57–59 |

| 14C28N | Mid-High | High | HRC 58–60 |

| D2 | High | Mid | HRC 60–62 |

| 440C | High | High | HRC 58–60 |

| Nitro-V | High | High | HRC 59–61 |

OEM/ODM Guidance: When Brands Should Spec 8Cr13MoV—and When to Step Up a Grade?

Brand market fit drives choice.

Spec 8Cr13MoV in mid-tier EDC lines, travel/city knives, and all-around folders aimed at mass market buyers. Upgrade in pro/tactical segments for more wear resistance.

Step up when:

- Customers demand longer edge life

- Heavy industrial/outdoor segment focus

- High-abrasion cutting environments

Care & Maintenance: Rust Prevention, Storage, and Quick Touch-Up Cadence?

Care makes steel last longer.

Keep blades clean and dry, store in cool environments, oil pivots lightly, and hone edges weekly with moderate use.

Stainless doesn’t mean rust-proof—saltwater and acids can mark blades if left untreated. Consistent light maintenance is better than infrequent heavy sharpening.

Conclusion

8Cr13MoV hits the balance many EDC buyers need—decent retention, good rust resistance, and easy sharpening at a sensible price, provided it’s used within its limits.