Steel choice shapes how a knife feels, performs, and lasts. 3Cr13 often appears in budget knives—some praise it for easy use, others dismiss it as “cheap steel.”

3Cr13 is a Chinese stainless steel similar to 420J2, known for affordability, high corrosion resistance, and ease of sharpening. It sacrifices edge retention for toughness and user-friendly maintenance.

In my factory work, I’ve seen how 3Cr13 maintains popularity with certain buyers. It’s not high-performance steel, but it delivers specific advantages for particular knife designs.

What Is 3Cr13? Composition and Common Equivalents?

3Cr13 is part of the Chinese Cr series stainless steels, patterned after older American and Japanese grades.

3Cr13 is roughly equivalent to 420J2 stainless steel—low carbon, high chromium, and optimized for corrosion resistance over edge retention.

Its typical composition:

| Element | % Content |

|---|---|

| Carbon (C) | ~0.3% |

| Chromium (Cr) | ~13% |

| Manganese (Mn) | ~1% |

| Silicon (Si) | ~1% |

| Phosphorus (P) | <0.04% |

| Sulphur (S) | <0.03% |

Low carbon means it can’t reach the hardness of mid- to high-end stainless steels. But with plenty of chromium, it resists rust well even in humid kitchens or near salt water.

I often explain it to brand clients as “a stainless workhorse for light-duty cutting.” The chemistry makes it very forgiving to work with at scale, which keeps prices low.

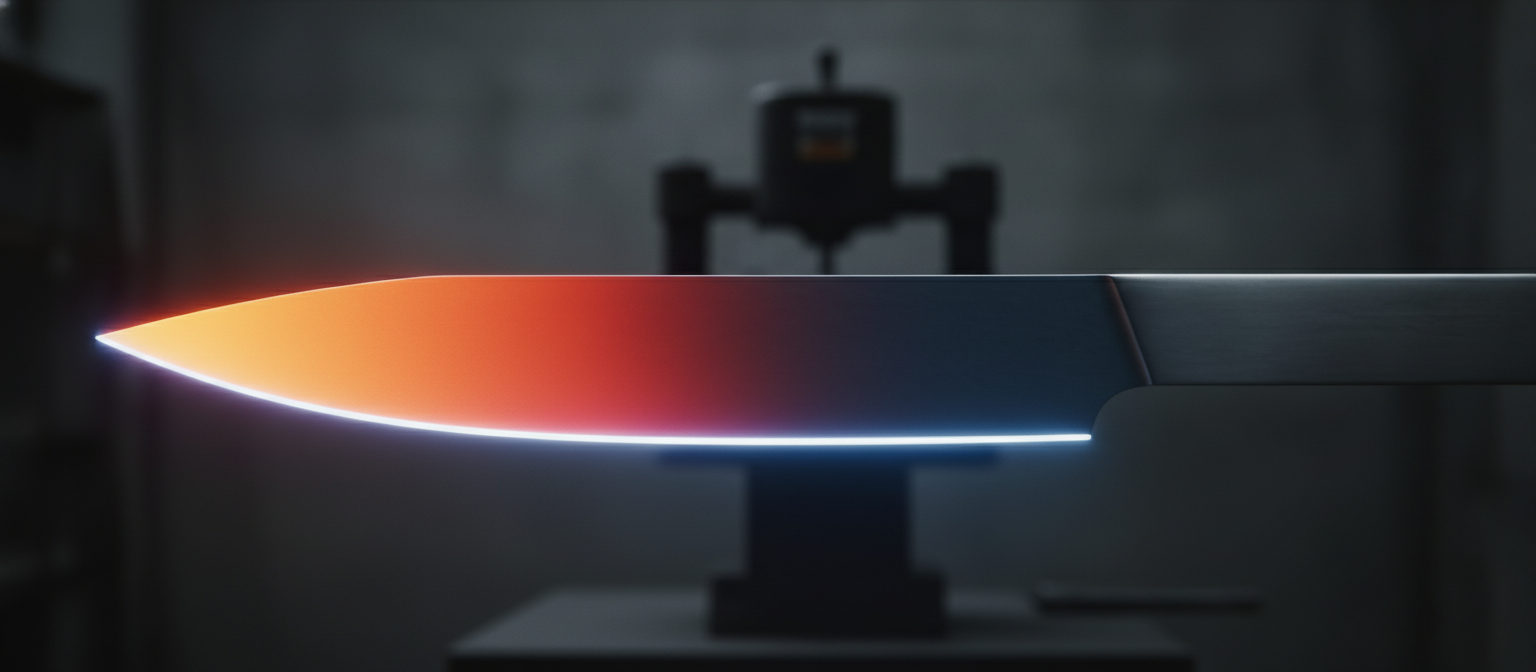

Typical Heat Treatment & Hardness (Around HRC 50–54): What That Means in Use?

Heat treatment determines hardness, toughness, and edge life for any steel.

Most 3Cr13 knives are hardened to around HRC 50–54, making them tough, flexible, and easy to sharpen but less wear-resistant.

In production, this is a simple, reliable heat treat—no exotic cycles. We can hit consistent hardness across batches without driving up scrap rate.

| Hardness Level | Key Benefit | Trade-Off |

|---|---|---|

| HRC 50–54 | Tough, hard to chip | Loses fine edge faster |

| Lower HRC (~50) | Max toughness | Shortest edge life |

| Higher HRC (~54) | Slightly better retention | Slightly more brittle |

At this hardness, cutting edges roll rather than chip when over-stressed. Rolled edges are easy to restore with a few passes on a stone.

This profile fits knives intended for casual users—those who prefer safety and easy maintenance to long-lasting hair-shaving sharpness.

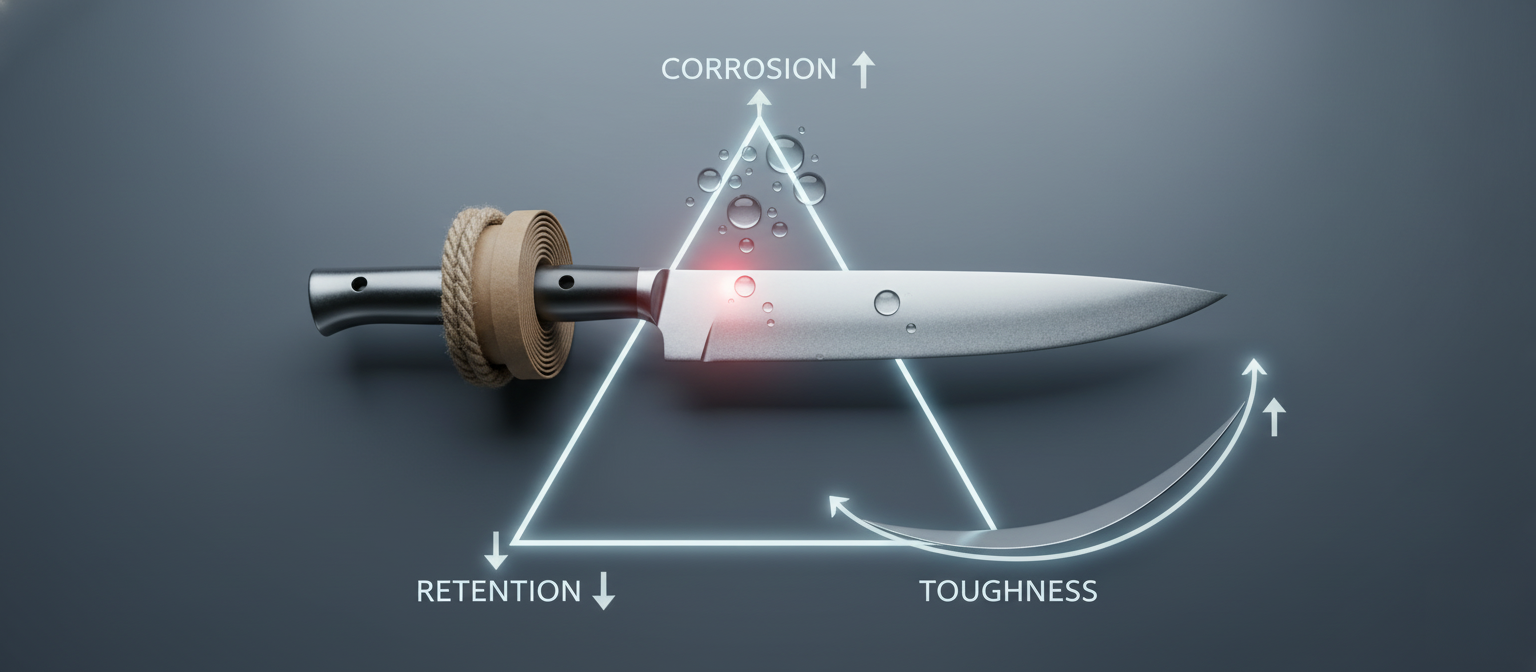

Performance Profile: Edge Retention, Corrosion Resistance, and Toughness Trade-Offs?

Every steel has its strengths and weaknesses. 3Cr13 shows clear performance patterns.

3Cr13 offers excellent corrosion resistance and toughness for light work, with modest edge retention due to its low carbon content.

Performance table:

| Attribute | Rating | Notes |

|---|---|---|

| Edge retention | Low | Will need frequent touch-ups |

| Corrosion resistance | High | Good in kitchens, outdoors |

| Toughness | Moderate-High | Resists chipping from drops |

| Ease of sharpening | Excellent | Beginner-friendly |

On fishing trips, I’ve seen 3Cr13 folders survive salt exposure with minimal spotting. But I’ve also had users complain they “go dull fast” after cutting cardboard for half an afternoon. That’s the expected trade-off.

It’s crucial for brands to match steel capability to customer usage. For example, outdoor bushcrafters want better retention than 3Cr13 can give. Kitchen hobbyists often prefer its rust-proof nature.

Where 3Cr13 Shines: Kitchen Utility, Light EDC, Gift/Entry-Level Knives?

Some buyers don’t need maximum edge life—they need a tool that’s safe and easy for occasional use.

3Cr13 performs well in kitchen knives, light-duty EDC folders, and entry-level or gift knives where corrosion resistance and affordability are priorities.

I’ve made countless OEM kitchen sets with 3Cr13. They ship sharp, resist stains over years, and can be revived with a quick honing. Beginners appreciate that stones or pull-through sharpeners work easily.

Common winning cases:

| Use Case | Advantage |

|---|---|

| Kitchen utility | Wash-safe, rust-resistant |

| Light EDC | Legal-friendly lengths, forgiving edges |

| Promotional/gift | Low cost, easy logo branding |

These niches often value presentation and reliability over performance specs. A gift knife that’s safe at low hardness—and looks good with custom finishing—fits perfectly.

Where It Struggles: Abrasive Media, Heavy Outdoor Tasks, Pro Duty Cycles?

Put 3Cr13 in the wrong role and you’ll meet its limits quickly.

3Cr13 wears quickly in abrasive cutting and under heavy chopping. It’s not suited for professional chefs, construction-grade utility, or long bushcraft outings.

In field tests on ropes, sand-impregnated cardboard, and wood splitting, 3Cr13 edges degrade much faster than steels with more carbon and carbide formation (e.g., D2, VG-10, 14C28N).

Signs it’s outside its comfort zone:

| Task | Performance Issue |

|---|---|

| Repeated abrasive cuts | Fast dulling |

| Hard impact chopping | Edge rolling |

| Long pro shifts | Frequent resharpening |

That’s why I caution industrial buyers—if the job sees high wear or requires cutting efficiency all day, step up to higher-tier stainless.

Sharpening Behavior: Beginner-Friendly Angles, Stones, and Quick Touch-Ups?

For a lot of buyers, sharpening ease equals satisfaction.

3Cr13 sharpens quickly at inclusive angles around 30–40° and responds well to medium/fine stones or simple ceramic rods.

This steel responds fast—just a minute or two to restore a utility edge. It’s ideal for pull-through sharpeners sold with entry-level knives.

I often recommend:

| Tool | Benefit |

|---|---|

| Medium water stone (800–1000 grit) | Quick regrind |

| Fine ceramic rod | Daily honing |

| Clamp sharpening jig | Beginner consistency |

Its low wear resistance means even small burrs lift easily. That makes it great for teaching new users sharpening basics.

Geometry Over Steel: Grinds and Blade Thickness That Make 3Cr13 Perform?

Blade design can offset steel limits.

Thin, high-flat grinds or hollow grinds make 3Cr13 slice cleanly and delay dulling compared to thicker utility profiles.

In OEM builds, I find a 2.5 mm spine and full-flat grind give the best kitchen and EDC performance. Wide edges reduce push effort, so even as the steel softens during use, cutting remains pleasant.

Configurations to avoid: very thick blades for chopping—these force more stress onto the modest edge retention.

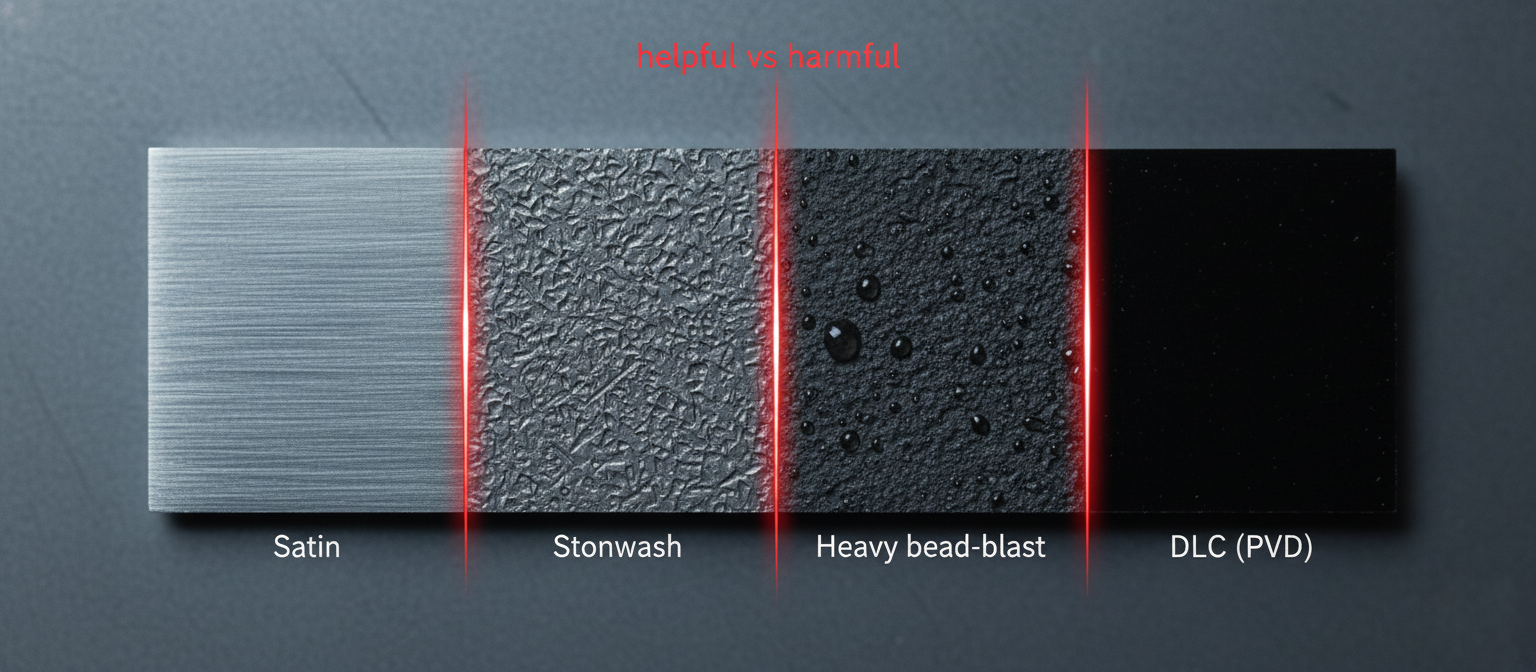

Finishes That Help: Stonewash, PVD/DLC, and Bead-Blast Cautions?

Finishing impacts corrosion and wear feel.

Stonewash hides scratches from soft steel. PVD/DLC can add surface hardness, but bead-blast finishes should be avoided for salt-prone use due to extra roughness.

Stonewash finish excels for gift knives—looks premium but conceals marks from soft blades. DLC coatings add scratch resistance and dark visual contrast.

Bead-blast finishes open surface texture, which can trap moisture and salt—hurting corrosion resistance despite high chromium.

QC Matters: Heat-Treat Variance, Tolerances, and Factory Consistency?

With 3Cr13, good factory control is the difference between “okay” and “disappointing” knives.

Consistent heat treat and grind tolerances keep 3Cr13 performing as intended—poor QC can make it dull faster or stain more easily despite its stainless nature.

I’ve seen identical steel grades perform miles apart due to factory variance. In our shop, we check hardness on each batch and test cut performance before shipping.

QC checklist:

| Step | Why It Matters |

|---|---|

| Hardness test (HRC) | Confirms spec |

| Grind symmetry check | Prevents wavey cuts |

| Passivation | Maximizes corrosion resistance |

Alternatives at Nearby Price Points: 5Cr15MoV, 7Cr17MoV, 8Cr13MoV, 14C28N?

Upgrading can improve specific properties without breaking budget.

Moving from 3Cr13 to steels like 5Cr15MoV or 8Cr13MoV adds edge retention while keeping corrosion resistance high.

Alternatives table:

| Steel | Carbon | Benefit |

|---|---|---|

| 5Cr15MoV | ~0.5% | Better edge life |

| 7Cr17MoV | ~0.7% | Higher wear resistance |

| 8Cr13MoV | ~0.8% | Balanced EDC performance |

| 14C28N | ~0.62% | Excellent edge + corrosion |

I guide buyers toward these if their users need more retention but can handle slightly longer sharpening times.

OEM/ODM Guidance: When to Spec 3Cr13 vs. Stepping Up a Grade?

Knowing customer habits helps choose steel wisely.

Spec 3Cr13 for low-impact, entry-tier projects—step up a grade for pro duty or abrasive use.

Good 3Cr13 projects:

- Kitchen sets for casual cooks

- Promotional knives with display focus

- Affordable EDC designs with light cutting tasks

Upgrade when:

- Target market is outdoors/professional

- Cutting media includes heavy cardboard, rope, wood

- Brand reputation depends on lasting sharpness

Buyer’s Checklist: How to Evaluate a 3Cr13 Knife Beyond the Steel Stamp?

A steel label doesn’t tell the whole story.

Look at heat treat spec, grind quality, finish choice, and handling in real tasks—not just “3Cr13” on paper.

Checklist:

| Factor | Why It Matters |

|---|---|

| Hardness spec | Confirms use-fit |

| Grind symmetry | Consistent cutting feel |

| Edge profile | Angle suits target tasks |

| Finish quality | Impacts corrosion, looks |

| Carry comfort | Matters for EDC folders |

Conclusion

3Cr13 isn’t a high-end performer, but with the right design and QC it delivers safe, rust-resistant performance for casual and entry-level users.