Choosing the right steel makes a pocket knife useful and reliable—or frustrating and short-lived. 4116 stainless steel divides opinion, especially among EDC and kitchen knife buyers.

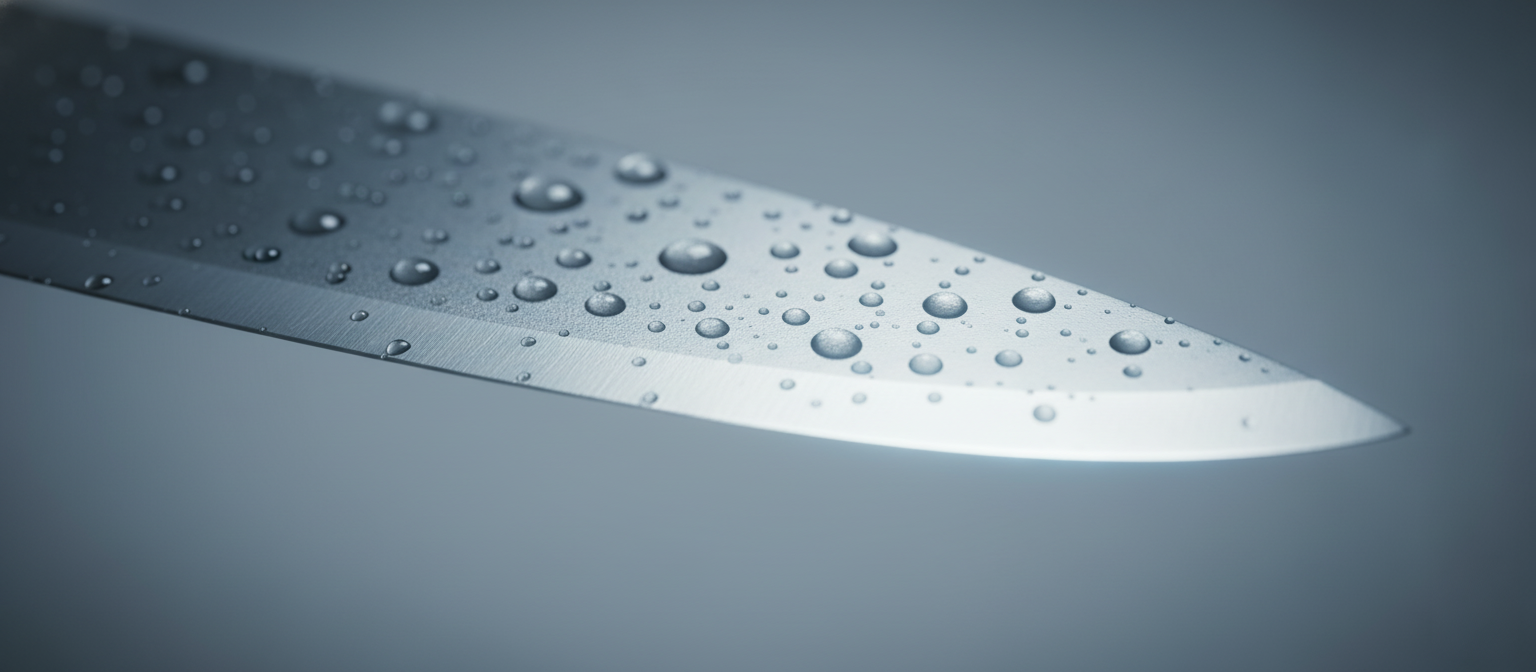

4116 is a German stainless steel similar to X50CrMoV15, known for high corrosion resistance, easy sharpening, and toughness. It trades long edge life for safety, stain resistance, and affordability.

I’ve built thousands of OEM knives with 4116. It shines in certain use cases, but not in others. Let’s break down what matters before you spec or buy.

Quick Answer: Who Should Pick 4116 (Pros & Cons in One Minute)?

If you need a quick verdict:

Pick 4116 for light EDC or food-prep knives where rust resistance and easy sharpening matter more than maximum edge retention. Avoid it for abrasive, high-torque, hard-use applications.

Pros:

- Excellent corrosion resistance

- Easy maintenance and sharpening

- Tough enough to resist chips

Cons:

- Modest edge retention

- Not ideal for prolonged heavy cutting

- Can roll edges with hard impact

What is 4116? Composition and Common Equivalents (X50CrMoV15 / 1.4116)?

4116 is part of a family of German cutlery steels designed for balanced performance in kitchens and general utility.

4116 is equivalent to X50CrMoV15 (DIN 1.4116), a stainless steel with ~0.5% carbon and ~15% chromium, designed for corrosion resistance and moderate hardness.

Typical composition:

| Element | % Content |

|---|---|

| Carbon (C) | ~0.50% |

| Chromium (Cr) | ~14–15% |

| Molybdenum (Mo) | ~0.80% |

| Vanadium (V) | ~0.10–0.20% |

| Manganese (Mn) | ~1% |

| Silicon (Si) | ~1% |

The molybdenum adds extra pitting resistance, and a touch of vanadium refines grain structure, aiding edge sharpness.

Heat Treatment Realities: Typical HRC Ranges and What They Mean in Use?

Heat treat determines where 4116 lands on the performance spectrum.

4116 in knives is typically hardened to HRC 55–57, balancing toughness with enough hardness for clean cuts without being brittle.

| HRC | Benefit | Trade-Off |

|---|---|---|

| 55–56 | Maximum toughness | Faster dulling |

| 56–57 | Balanced | Still soft vs. premium steels |

In production, this steel heat treats reliably with low batch failure. It handles grinding well and keeps warping minimal.

At softer hardness levels, you get forgiving edges that roll, not chip, under strain—making them easy to restore.

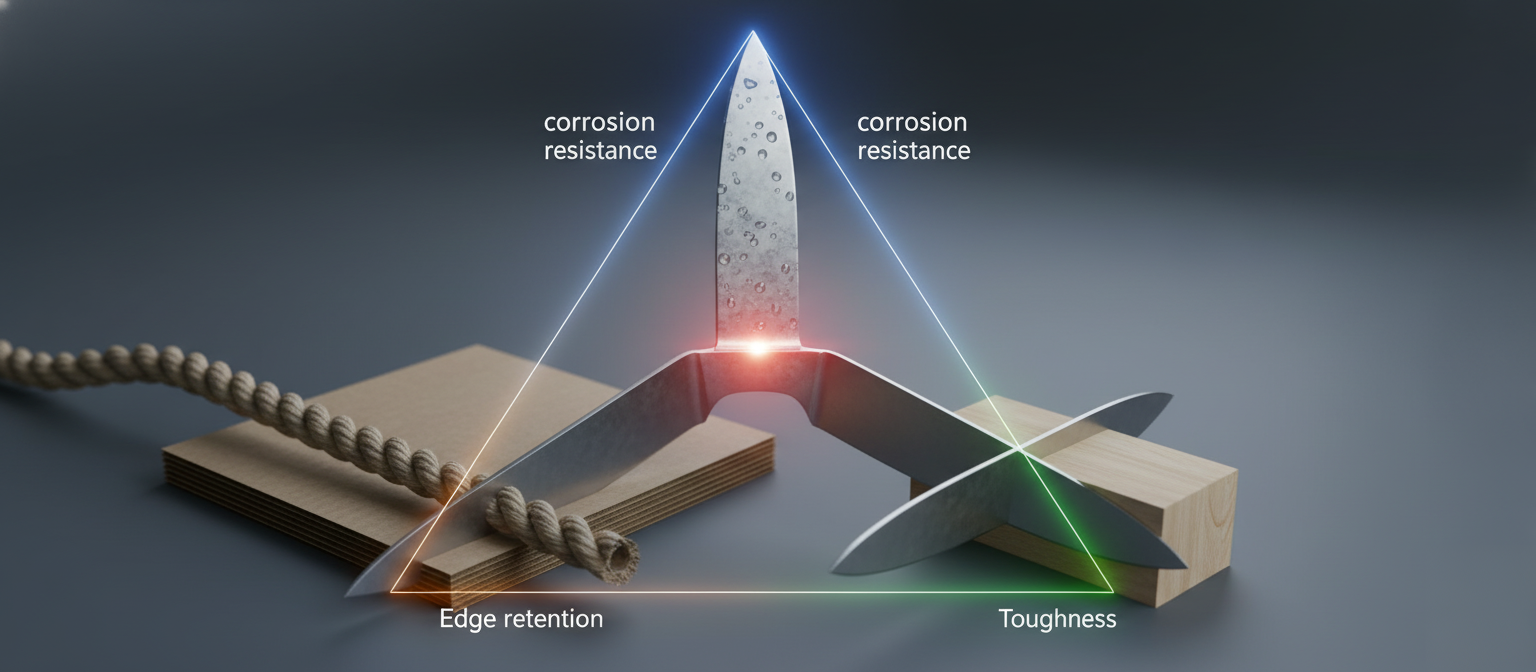

Performance Profile: Edge Retention, Corrosion Resistance, Toughness Trade-Offs?

Like any steel, 4116 balances multiple properties.

4116 offers high corrosion resistance and toughness, with modest edge retention due to lower carbide volume compared to harder stainless steels.

| Property | Rating | Note |

|---|---|---|

| Edge retention | Moderate-Low | Needs regular touch-ups |

| Corrosion resistance | High | Suitable for wet/food environments |

| Toughness | High | Resists chips and cracks |

| Ease of sharpening | Excellent | Simple to maintain |

I’ve had 4116 knives resist rust after hours in a damp tackle box—a win for anglers and chefs, even though they’ll need honing more often.

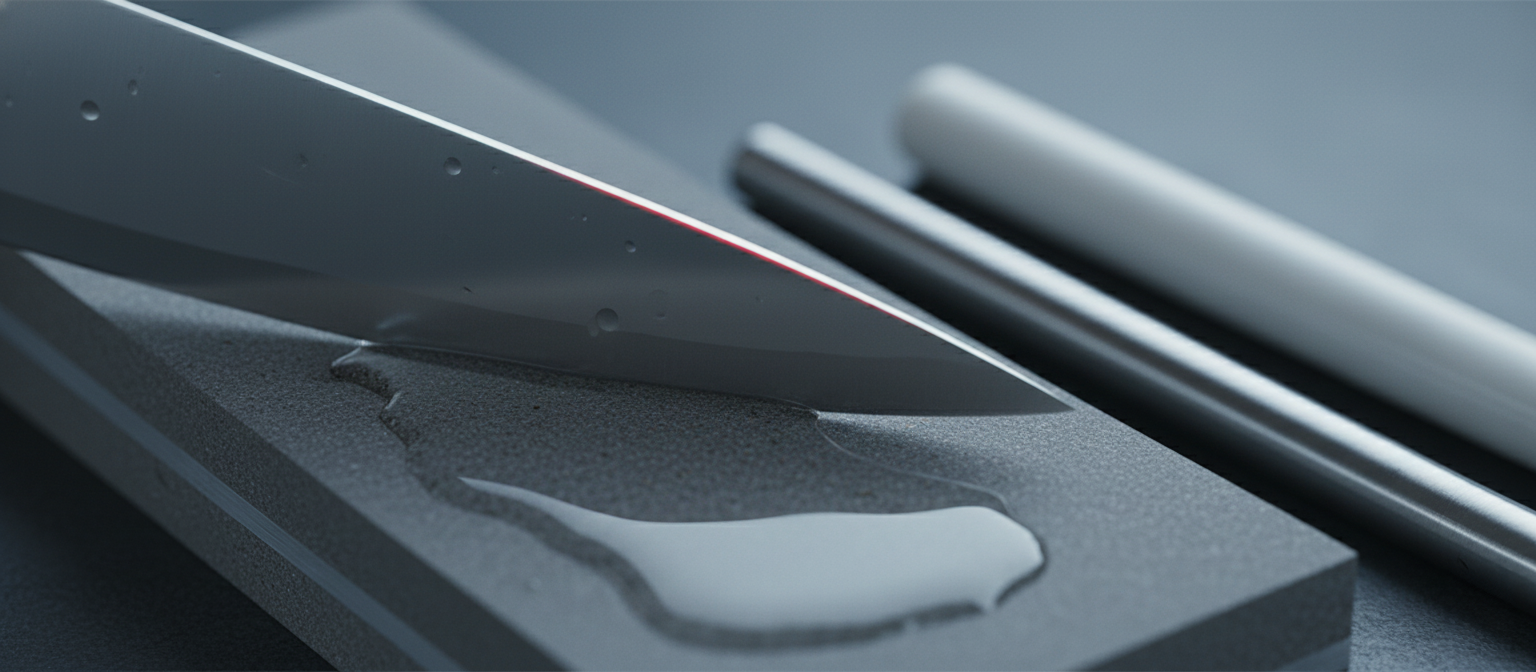

Sharpening Behavior: Recommended Angles, Stones, and Quick Touch-Ups?

Sharpening speed is one of 4116’s strong suits.

Best results come with inclusive angles around 30–40°, medium/fine grit stones, and ceramic or steel honing rods for maintenance.

| This steel burrs easily and responds to few passes. Ideal tools: | Tool | Advantage |

|---|---|---|

| 800–1000 grit stone | Fast regrind | |

| Fine ceramic rod | Daily edge maintenance | |

| Pull-through sharpener | For beginner users |

Its forgiving edge lets new users learn sharpening without risk of damage.

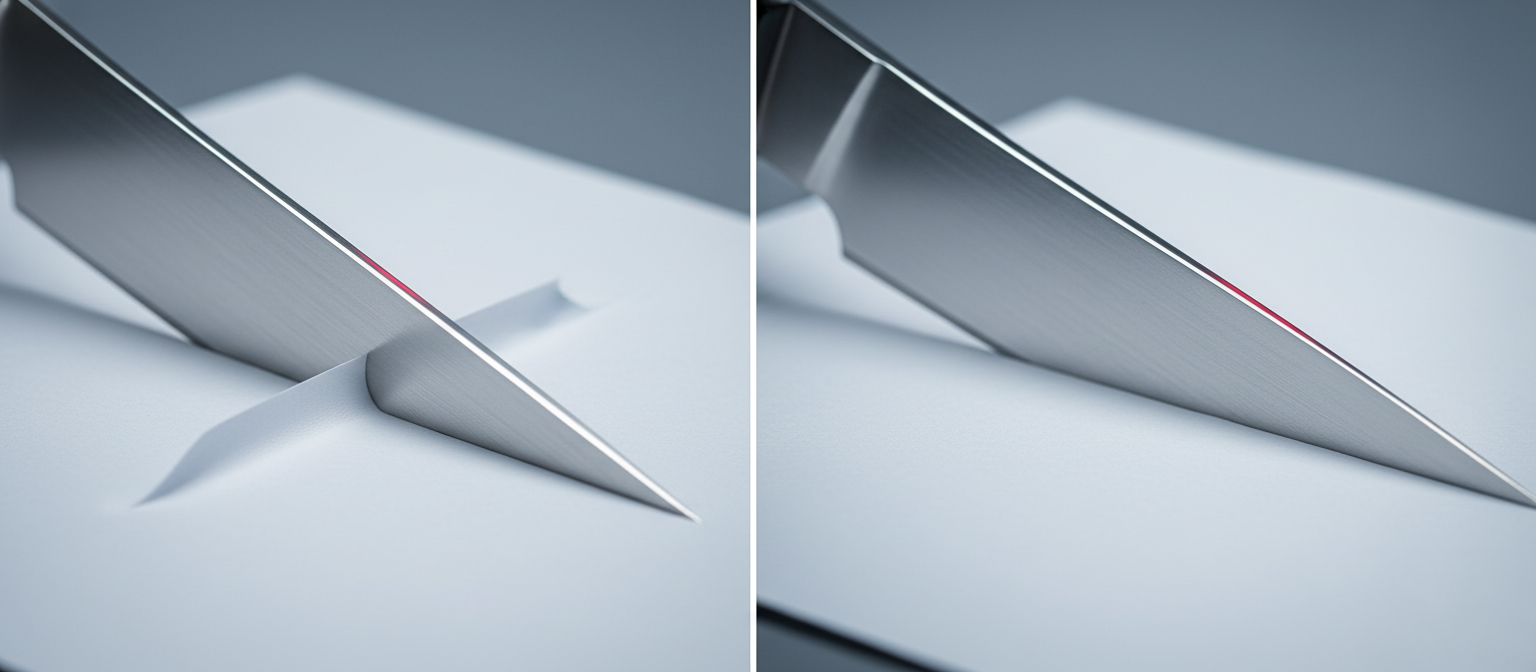

Geometry Over Steel: Blade Stock, Grind, and Edge Thickness That Make 4116 Shine?

Blade design can compensate for steel’s limits.

Thin blade stock (2–3 mm) and fine grinds—flat or hollow—help 4116 cut smoothly and make dulling less noticeable.

In my builds, drop points with full-flat grinds give best results for slicing tasks. A thin edge reduces cutting force and extends usable sharpness even with softer steel.

Avoid overly thick blades intended for heavy impact—this pushes 4116 beyond its optimal profile.

Best Use Cases: Light EDC, Food Prep, Urban Carry, and Gift/Entry-Level Knives?

Match steel to the job.

4116 excels in small EDC folders, kitchen utility knives, urban carry tools, and promotional/gift knives requiring stain resistance and safe hardness.

| Use Case | Benefit |

|---|---|

| Light EDC | Comfortable maintenance |

| Food prep | Hygienic and rust-resistant |

| Urban carry | Legal-friendly lengths |

| Gift knives | Low cost, attractive finish |

Great for buyers who want a clean stainless look and a knife that stays safe and serviceable over years.

Where It Struggles: Abrasive Media, Hard Use, and Pro Duty Cycles?

Don’t push soft steels too far.

4116 loses edge quickly in abrasive materials, struggles in sustained hard cutting, and isn’t ideal for pro trades needing all-day performance.

| Challenges: | Task | Issue |

|---|---|---|

| Cardboard overload | Fast dulling | |

| Rope-heavy work | Edge rolling | |

| Wood splitting | Not intended |

For demanding EDC or bushcraft, customers are often happier stepping up to harder steels.

Finishes That Help (and Hurt): Stonewash/Satin vs. Heavy Bead-Blast and Coatings?

Finish affects look and corrosion results.

Satin and stonewash suit 4116 well—easy upkeep and scratch hiding. Heavy bead-blast can trap moisture and hurt corrosion resistance.

DLC/PVD coatings add surface hardness but won’t fix edge retention limits—still useful for visual style or branding.

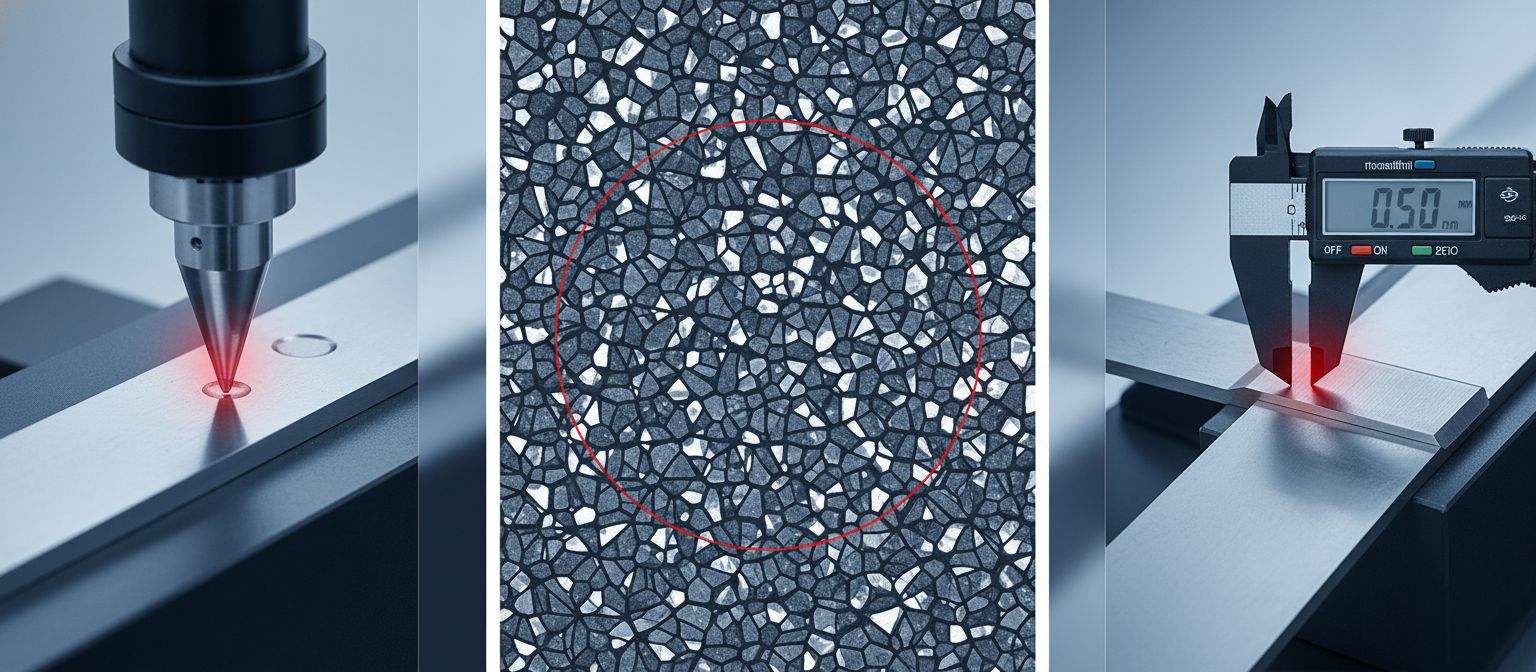

Quality Variables: Mill Cleanliness, Heat-Treat Consistency, and QC Tolerance?

Small production variations can swing performance.

Mill cleanliness affects corrosion resistance; consistent heat treat keeps hardness in target; tight QC tolerances ensure predictable cutting feel.

I reject batches if hardness tests drift more than 1 HRC from spec or if surface defects suggest mill contamination—these flaws hurt final user trust.

Close Alternatives by Budget: 5Cr15MoV/420HC (Lateral), 12C27/14C28N/8Cr13MoV (Step-Ups)?

Alternatives can shape price and performance.

5Cr15MoV and 420HC offer similar balance; 12C27 and 14C28N improve retention at higher hardness; 8Cr13MoV gives a mid-step with broader EDC appeal.

| Steel | Edge Retention | Corrosion | Typical Hardness |

|---|---|---|---|

| 5Cr15MoV | Low | High | HRC 55–57 |

| 420HC | Low-Mid | High | HRC 56–58 |

| 12C27 | Mid | High | HRC 57–59 |

| 14C28N | Mid-High | High | HRC 58–60 |

| 8Cr13MoV | Mid | Mid-High | HRC 58–60 |

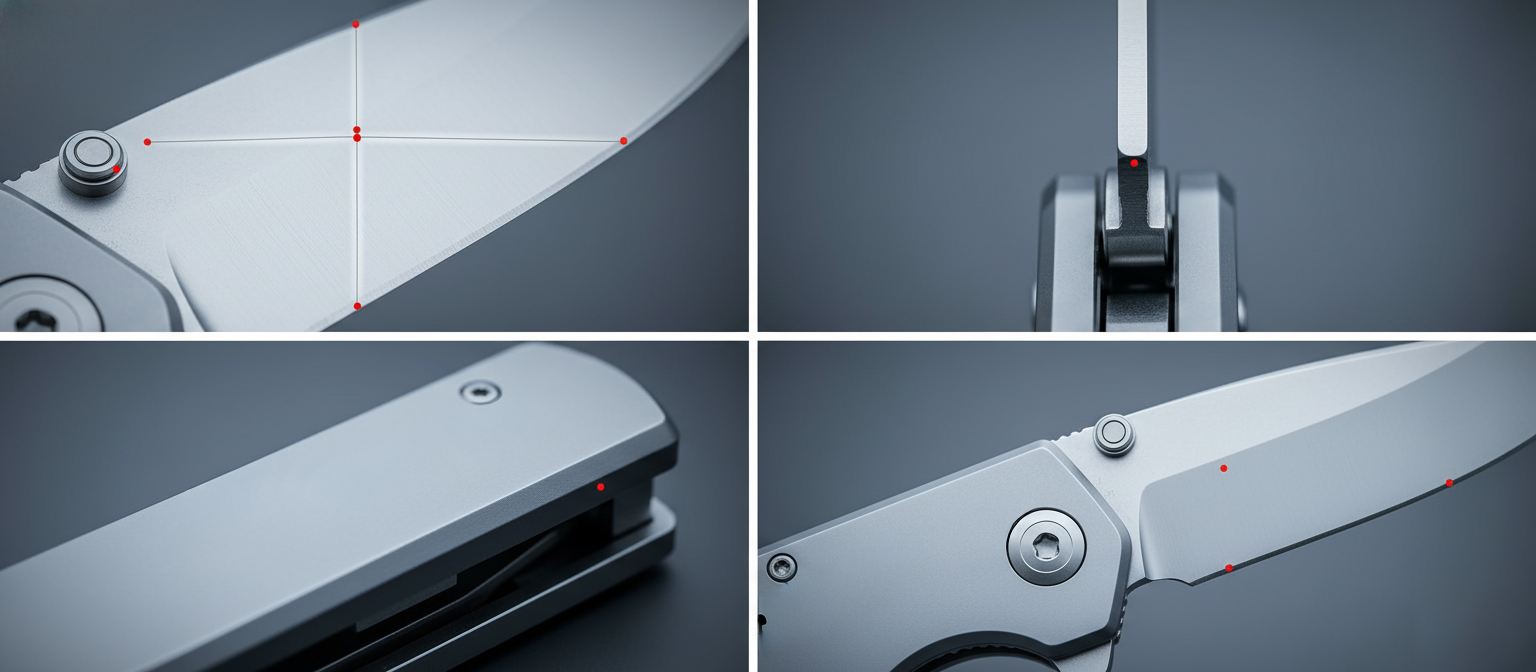

Buyer’s Checklist: How to Evaluate a 4116 Pocket Knife Beyond the Steel Stamp?

Steel type isn’t enough—validate the knife build.

Check hardness spec, grind profile, finish, and QC records, not just “4116” on the product sheet.

Checklist:

- Hardness in HRC range

- Centered blade grind

- Finish-free of corrosion traps

- Comfortable ergonomics

- Reliable pivot action

OEM/ODM Guidance: When Brands Should Spec 4116—and When to Move Up a Grade?

Brand positioning drives the steel choice.

Spec 4116 for price-sensitive markets wanting corrosion resistance and ease of use; step up to harder steels for professional or heavy-duty positioning.

Good fit:

- Kitchen/ECD crossover knives

- Promotional merchandise

- Entry-level gift sets

Upgrade when:

- Target segment demands long edge life

- Outdoor/tactical focus

- Heavy industrial use expected

Conclusion

4116 stainless steel succeeds when buyers value rust resistance, safety, and easy sharpening over maximum edge retention—ideal in entry-level and food-safe knife designs.