7Cr17MoV is a budget stainless steel favored for its strong rust resistance and ease of maintenance. It’s a common choice for entry-level folders and kitchen knives.

Choose 7Cr17MoV if corrosion resistance matters most and maximum edge retention isn’t required. Avoid it if you need a long-lasting edge in abrasive or heavy-duty tasks.

I’ve built OEM knives with this steel for brands targeting humid or coastal markets. With proper use, it’s dependable and user-friendly.

Quick Answer: Who Should (and Shouldn’t) Choose 7Cr17MoV?

7Cr17MoV suits certain buyers well.

Pick 7Cr17MoV for light EDC, food-safe knives, and gifts in moisture-heavy environments. Skip it for prolonged hard cutting in industrial or bushcraft contexts.

Pros:

- High corrosion resistance

- Easy sharpening and upkeep

- Affordable for wide distribution

Cons:

- Modest edge retention

- Can roll or dull with hard impact

- Not for long abrasive cycles

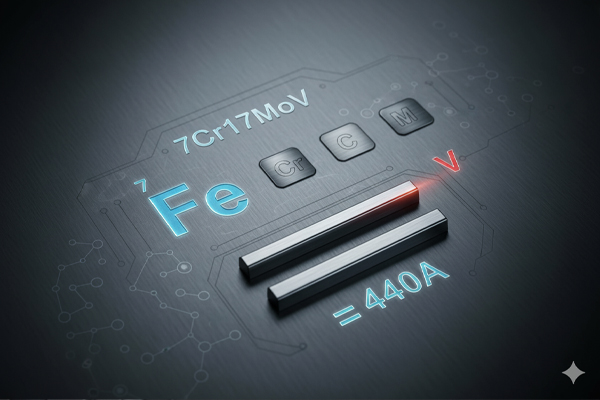

What is 7Cr17MoV? Chemistry and Common Equivalents (≈ 440A with Mo/V)?

7Cr17MoV is a Chinese stainless steel inspired by 440A, with added molybdenum and vanadium.

It has ~0.7% carbon and ~17% chromium, plus Mo and V for better corrosion resistance and finer grain.

Typical composition:

| Element | % Content |

|---|---|

| Carbon (C) | ~0.70% |

| Chromium (Cr) | ~16.5–17% |

| Molybdenum (Mo) | ~0.50% |

| Vanadium (V) | ~0.10–0.20% |

| Manganese (Mn) | ~1% |

| Silicon (Si) | ~1% |

High chromium drives rust prevention, molybdenum helps with pitting resistance, and vanadium improves wear slightly.

Typical Heat-Treat Ranges (Approx. HRC 56–58) and What They Mean in Use?

Heat treatment shapes final performance.

7Cr17MoV is usually hardened to HRC 56–58, emphasizing toughness and rust resistance, with enough hardness for daily slicing tasks.

| HRC | Benefit | Trade-Off |

|---|---|---|

| 56 | Maximum toughness | Faster dulling |

| 57 | Balanced | Still soft for some |

| 58 | Slightly longer edge life | Marginally less forgiving |

Proper heat treat ensures it avoids chipping and stays safe for beginner users.

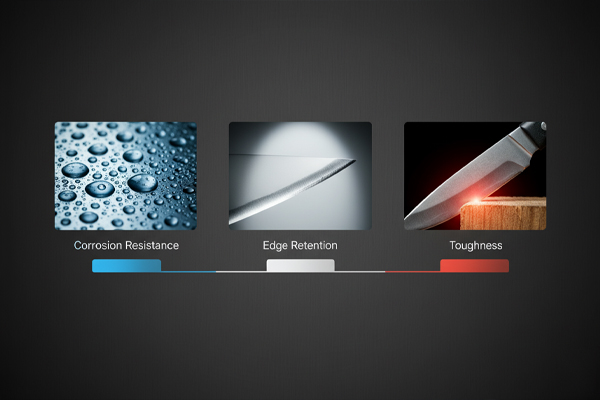

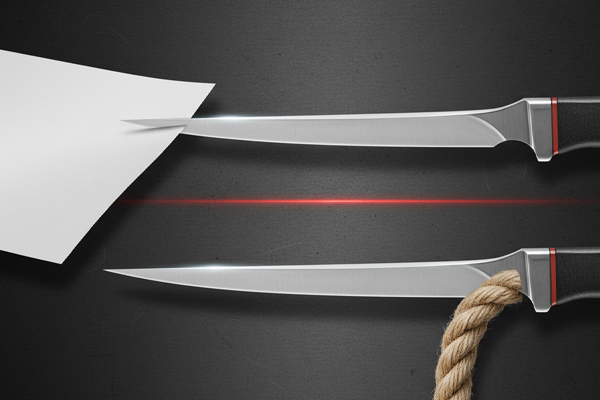

Performance Profile: Corrosion Resistance, Edge Retention, Toughness Trade-Offs?

Rust protection is where this steel shines.

You get high corrosion resistance, moderate edge retention, and strong toughness, making it ideal for wet or food-contact environments.

| Property | Rating | Note |

|---|---|---|

| Edge retention | Moderate-Low | Needs more frequent honing |

| Corrosion resistance | Very high | Safe for coastal/humid use |

| Toughness | Good | Resists chips in light cutting |

| Ease of sharpening | Excellent | Responds to basic tools well |

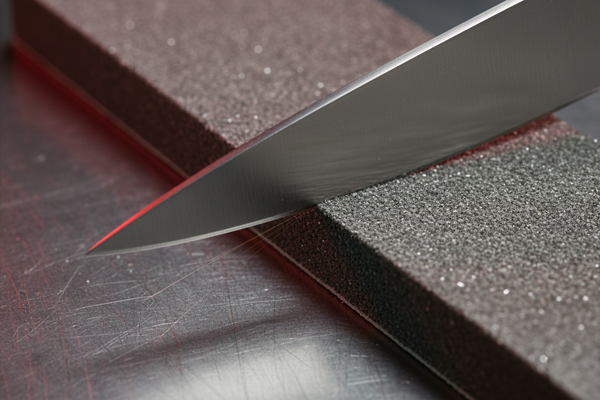

Sharpening Behavior: Friendly Angles, Stones, and Stropping Cadence?

Sharpening is simple with this steel.

Use ~30–40° inclusive edge angles, medium grit stones, and stropping weekly for consistent bite.

| Recommended workflow: | Tool | Role |

|---|---|---|

| 1000 grit stone | Primary edge refresh | |

| Leather strop | Maintains polish and bite | |

| Ceramic rod | Fast touch-ups in use |

Because of its softness, light honing can restore sharpness in seconds.

Geometry Over Steel: Stock Thickness, Grind, and Edge Width That Make It Shine?

Blade design makes a big difference here.

Thin stock and narrow edge widths help 7Cr17MoV cut efficiently and extend usable sharpness. Flat or hollow grinds work well for general slicing.

In production runs, I prefer 2–2.5 mm stock thickness and fine tips to keep performance snappy.

Surface Finishes That Help (and Hurt): Satin/Stonewash vs. Heavy Bead-Blast; Coatings?

Finish selection affects corrosion behavior.

Satin or stonewash keeps maintenance easy. Heavy bead-blast can trap moisture, and coatings add style but don’t improve edge durability.

In marine markets, I avoid bead-blast without sealing—the risk of hidden rust spots is higher.

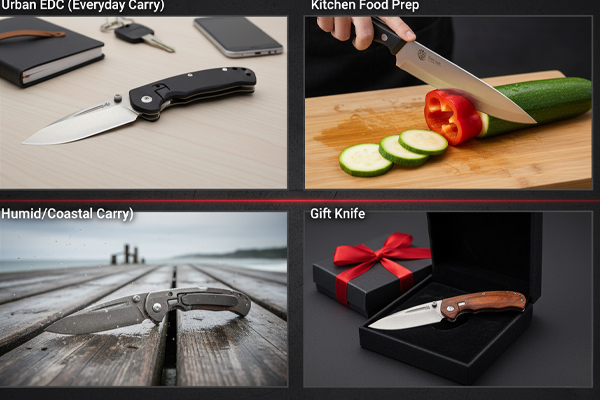

Best Use Cases: Urban EDC, Food Prep, Humid/Coastal Carry, Gift/Entry-Level Knives?

Match use to steel strengths.

7Cr17MoV works best in kitchen knives, compact EDC for city use, gifts for casual users, and knives in salt-prone zones.

| Use Case | Benefit |

|---|---|

| Urban EDC | Easy upkeep |

| Food prep | Strong hygienic profile |

| Coastal carry | Resists salt exposure |

| Gift knives | Affordable quality |

Where It Struggles: Abrasive Media, Prolonged Hard Use, Prying/Batoning?

Keep it inside its lane.

7Cr17MoV dulls fast on abrasive cuts, fades in extended heavy work, and can distort if used for prying or batoning.

It’s not engineered for hard industrial uses—step up to wear-resistant steels for that.

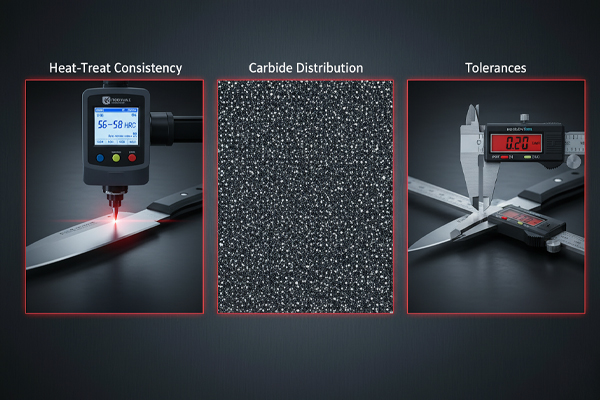

QC Variables to Watch: Heat-Treat Consistency, Carbide Distribution, Tolerances?

QC can make or break factory output.

Check hardness samples, look for consistent grind symmetry, and verify surface cleanliness before accepting batches.

Uniform carbide distribution improves edge smoothness and maintenance response.

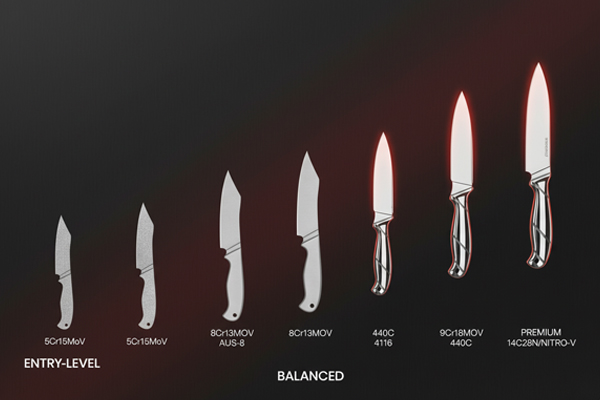

Close Alternatives by Budget & Feel: 5Cr15MoV, 8Cr13MoV, 9Cr18MoV/440C, 4116, AUS-8, 14C28N, Nitro-V?

Know what else fits similar use cases.

Lower range: 5Cr15MoV. Balanced options: 8Cr13MoV, AUS-8, 4116. Higher corrosion with more retention: 9Cr18MoV, 440C, 14C28N, Nitro-V.

| Steel | Retention | Corrosion | Hardness |

|---|---|---|---|

| 5Cr15MoV | Low | High | HRC 55–57 |

| 8Cr13MoV | Mid | Good | HRC 57–59 |

| AUS-8 | Mid | Good | HRC 57–59 |

| 4116 | Low-Mid | High | HRC 55–57 |

| 9Cr18MoV | Mid-High | High | HRC 58–60 |

| 440C | Mid-High | High | HRC 58–60 |

| 14C28N | High | High | HRC 58–60 |

| Nitro-V | High | High | HRC 59–61 |

Buyer’s Checklist: How to Evaluate a 7Cr17MoV Knife Beyond the Steel Stamp?

Steel name alone doesn’t define quality.

Look for spec-confirmed hardness, clean fit and finish, smooth lock action, and grind precision.

Checklist:

- HRC 56–58 range

- Centered blade grind

- Rust-resistant finish type

- Comfortable handle shape

- Reliable lockup and pivot smoothness

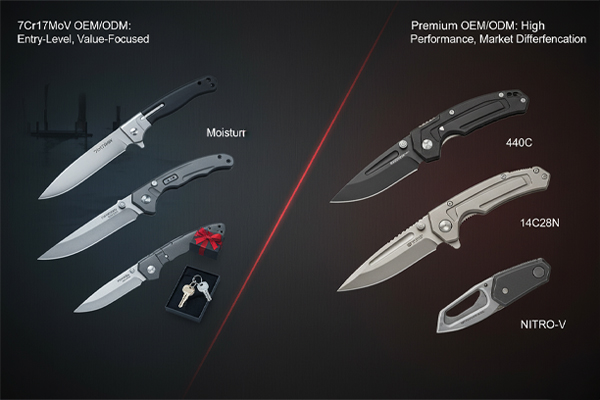

OEM/ODM Guidance: When Brands Should Spec 7Cr17MoV—and When to Step Up a Grade?

Match steel choice to target user expectations.

Spec 7Cr17MoV for moisture-prone, entry-level markets. Step up for buyers demanding higher edge retention and wear resistance.

Best fit:

- Coastal EDC lines

- Kitchen and gift sets

- Promotional knives with practical use

Upgrade when:

- Target market is heavy use

- Abrasive cutting tasks are common

- Tactical/outdoor positioning is desired

Care & Maintenance: Rust Prevention, Storage, and Quick Touch-Up Schedule?

Steel is forgiving but still needs care.

Rinse and dry after use, store in low-humidity environments, and oil pivot lightly. Hone edge weekly with moderate use.

Even high-chromium steels will spot or stain if neglected. Maintenance keeps performance consistent.

Conclusion

7Cr17MoV offers strong rust protection, dependable toughness, and easy upkeep—ideal for entry-level EDC and food-safe knives in humid markets, provided edge life expectations are realistic.